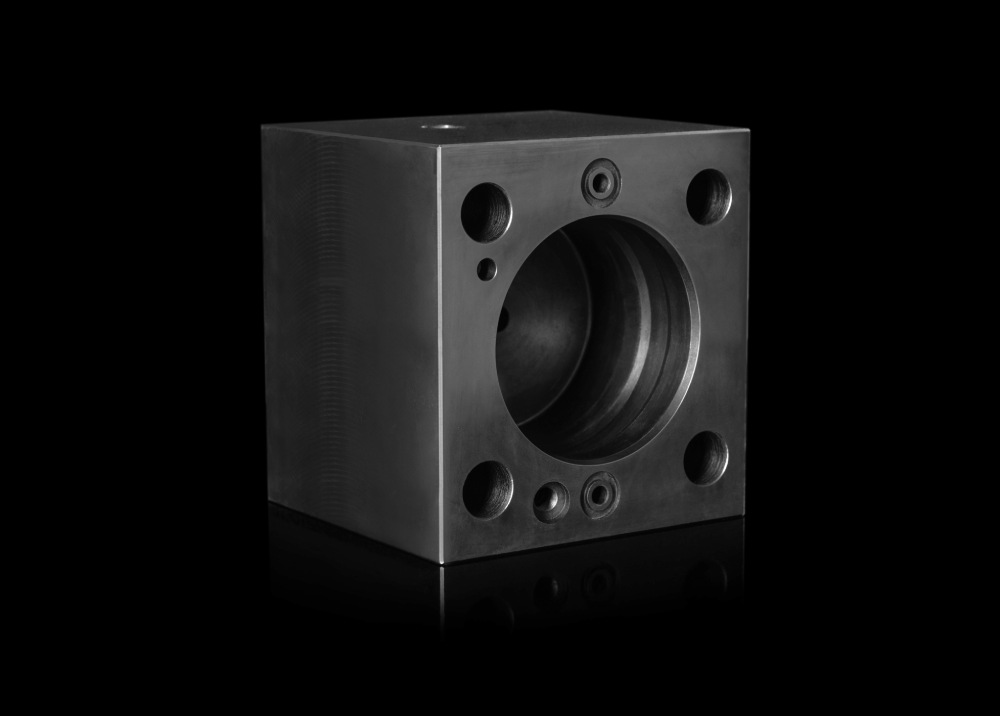

Gamba Specialisti in lavorazioni meccaniche complesse

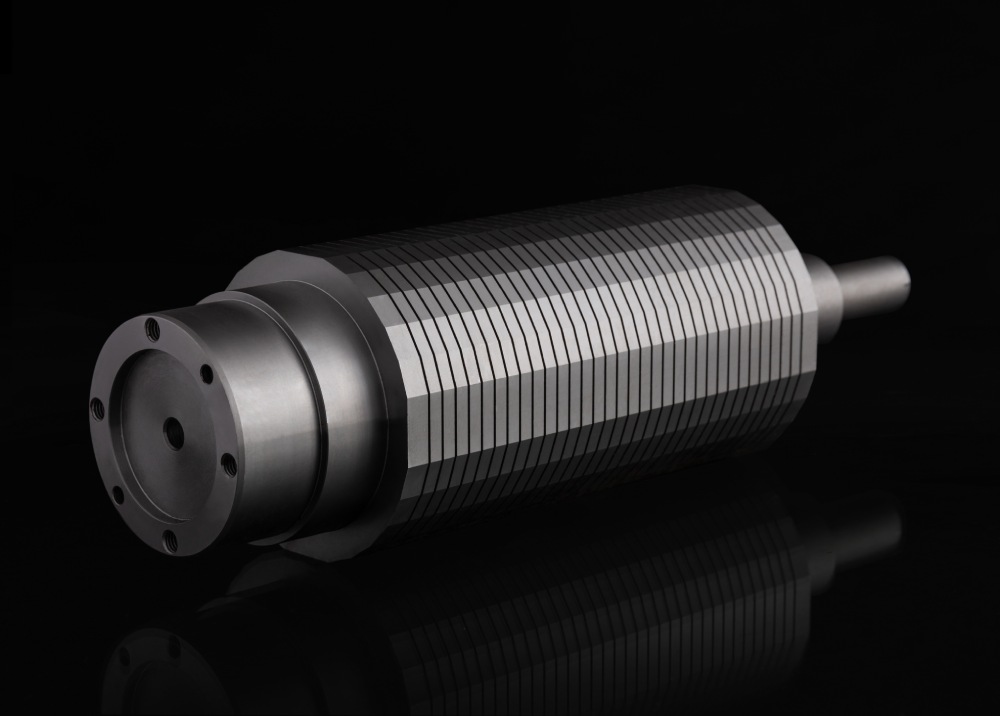

Specialisti in lavorazioni meccaniche complesse su materiali difficili

La nostra vocazione è la complessità. Assistiamo i nostri clienti nei loro progetti più importanti, quando un piccolo particolare ha un grande valore per il successo del prodotto finale.

-

Lotti di produzione di media e grande dimensione. Con macchine mono o doppio mandrino

-

Tutti i materiali esclusa la ghisa. Principalmente acciai legati.

-

Dimensioni da 2 a 500 mm

I settori di riferimento

Lo stabilimento a Val Brembilla

Lo stabilimento Gamba è a Val Brembilla, un importante polo della meccanica di precisione in provincia di Bergamo.

Tutto prodotto internamente

Gamba ha un ampio parco macchine costantemente aggiornato. Esegue internamente tutte le lavorazioni per garantire la qualità del prodotto finale e il rispetto dei tempi di consegna. Solo i trattamenti termici e galvanici sono commissionati a fornitori qualificati.

1

Tornitura

2

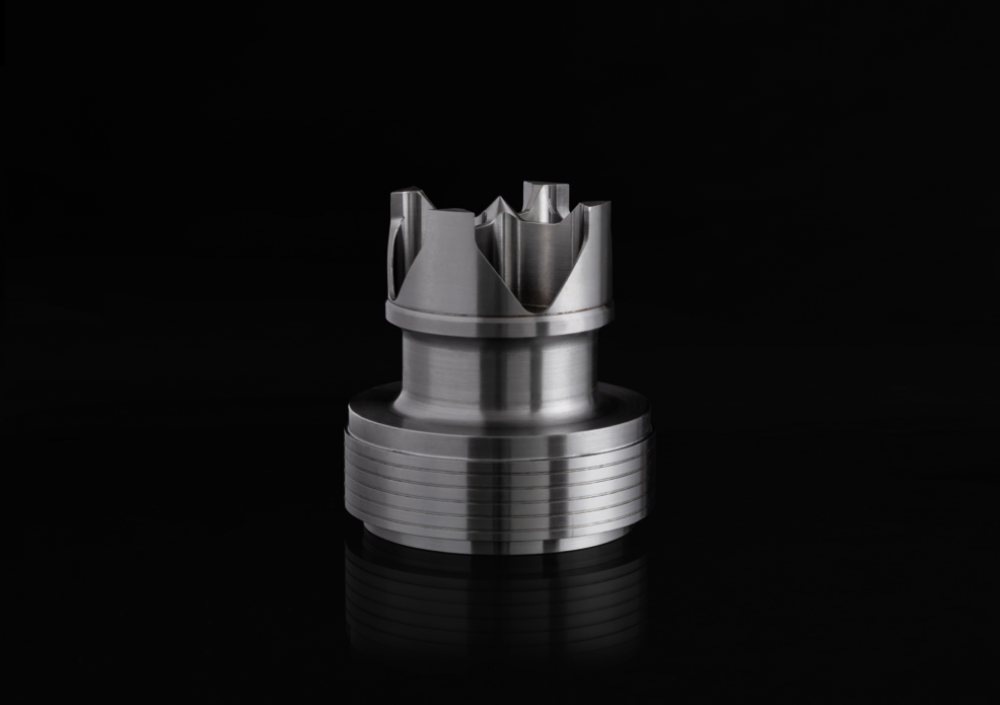

Fresatura

3

Rettifica e lappatura

4

Minuterie

1

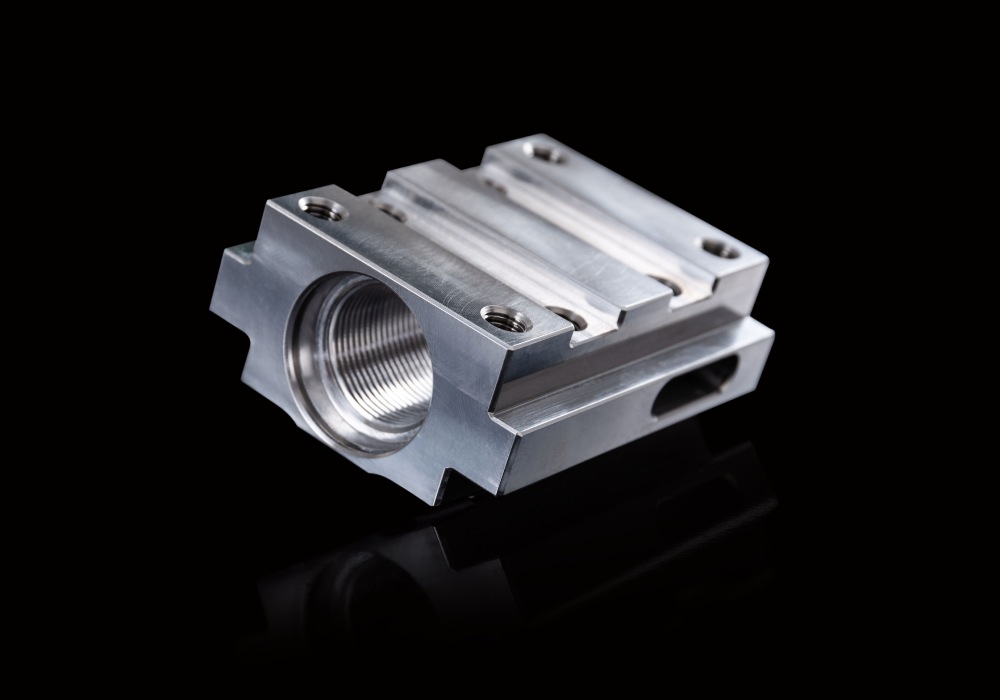

Tornitura

1

Tornitura

34 torni CN

- 14 torni da barra con passaggio barra fin a 65 mm

- 6 torni da ripresa con caricamento automatico e diametro max 150 mm

- 6 torni con caricamento manuale per diametri fino a 280 mm

- 3 torni in allestimento hard turning e caricamento automatico

- 5 torni a fantina mobile CN con passaggio barra fino a 20 mm

2

Fresatura

2

Fresatura

15 centri di lavoro verticali ISO 40 con mandrini fino a 20.000 giri/min e potenze fino a 25 Kw

- 6 centri di lavoro a 5 assi con tavola fino a 630 mm

- 4 centri di lavoro con doppio pallet

- 5 centri di lavoro a 3 o 4 assi con tavola fino a 1000 mm

3

Rettifica e lappatura

3

Rettifica e lappatura

14 rettifiche di diversa tipologia

- 4 CN per esterni o interni/esterni max 130 mm

- 2 per esterni idrauliche con misuratore elettronico in process

- 1 CN senza centri max 80 mm

- 4 senza centri idrauliche

- 1 CN tangenziale max 650 mm

- 1 lappatrice verticale CN max 120 mm

- 1 lappatrice orizzontale max 25 mm

4

Minuterie

4

Minuterie

Un ampio parco macchine per lavorazioni di minuteria e di ripresa

- 60 torni a camme per diametri da 2 a 25 mm

- 23 transfer

- 3 rullatrici

- 2 dentatrici

Casi studio

Come abbiamo supportato i nostri clienti, dalla progettazione delle componenti tecniche alla fornitura.

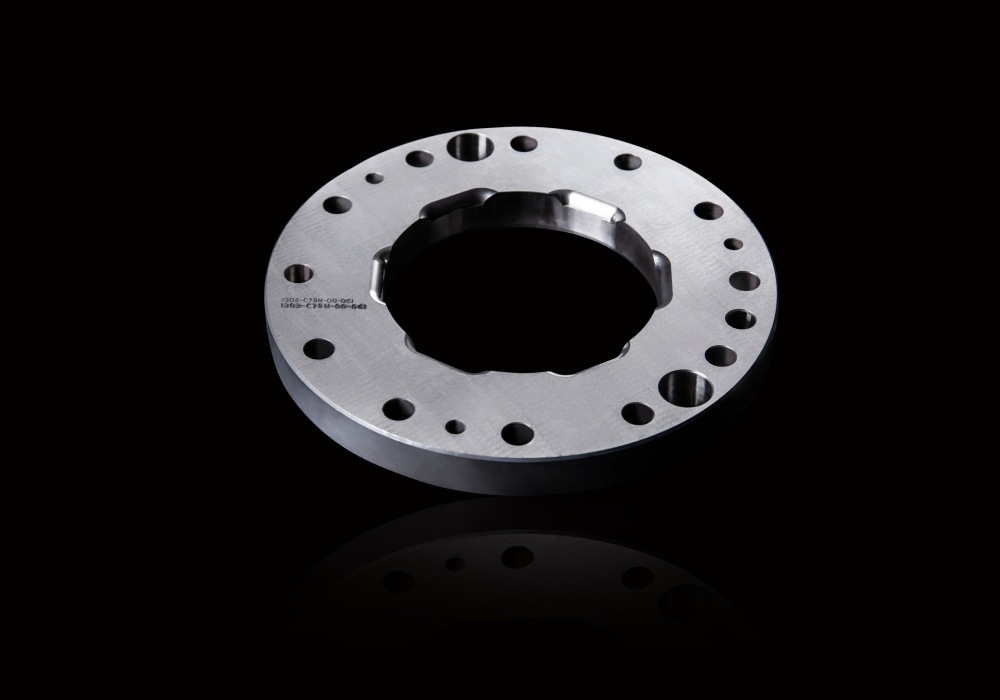

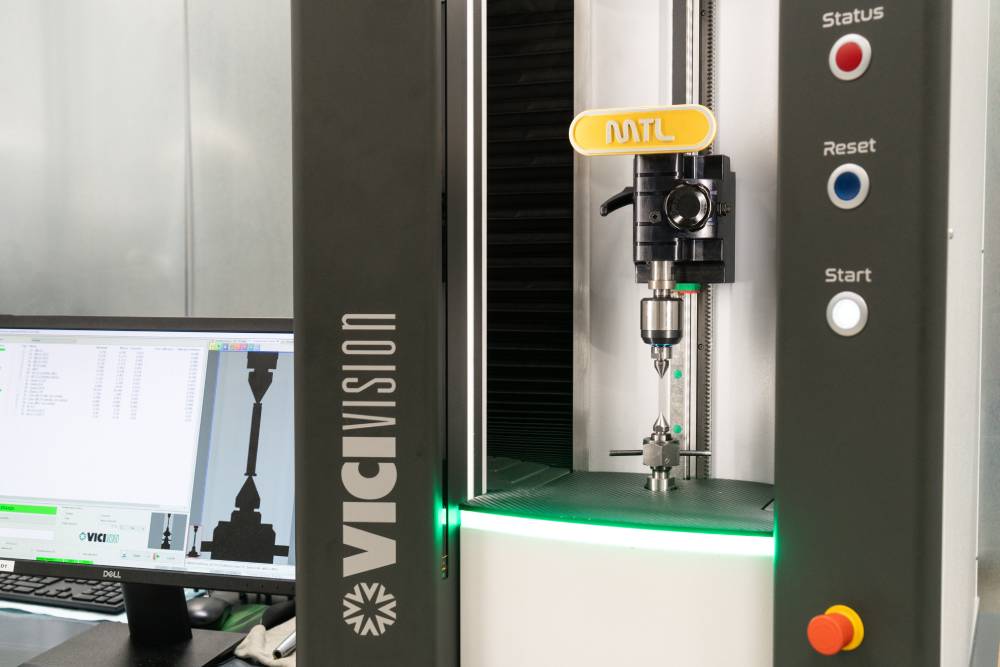

Qualità certificata

Il servizio qualità garantisce tolleranze geometriche e dimensionali anche di pochi millesimi su componenti complessi.

La garanzia Gamba

Gamba dà molta importanza a servizi tecnici che rafforzano l’affidabilità produttiva e logistica.

Un team di 10 persone con competenze meccaniche, elettriche ed elettroniche assiste la produzione riducendo la dipendenza da fornitori esterni.

Il team Gamba

- Costruisce utensili speciali ed attrezzature;

- Progetta e realizza automazioni di produzione e di controllo;

- Provvede alle manutenzioni di impianti e macchinari.

Vorresti maggiori informazioni?

Compila il modulo di contatto oppure contattaci direttamente ai seguenti recapiti: