Year of foundation

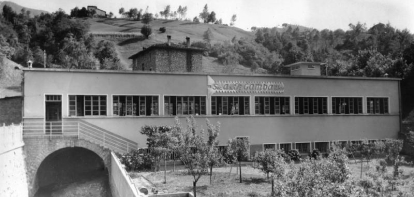

The Gamba Brothers Limited Company was founded in Milan. These were the years of the embargo and autarchy to which the company contributed with the production of unified screws, products that were previously imported.

It specialises in the manufacture of complex components using materials that are difficult to machine.

Gamba supports customers in their most important projects, where every little detail is essential to the success of the product.

Gamba manufactures all machining stages in-house to ensure reliability, along with respect for drawing dimensions and delivery times.

It offers services that include design consultancy, the creation of prototypes, the realisation of production batches , as well as the testing and assembly of complex components.

It collaborates with specialised partners in design machining, especially large parts, precision carpentry, as well as standardised and customised screws. Icovia offers mechanical solutions.

Over the years, Gamba has been able to adapt to every change that the historical moment demanded, demonstrating great adaptability and innovation.