Quality control meets the reliability expectations of complex productions

Dimensional and geometric tolerances of even a few microns.

Quality Control

The quality control team consists of 10 highly specialised people, who:

- guarantee the quality of production processes;

- manage the instrumentation supporting production;

- interface with customers for continuous process improvement;

- provide dimensional certification.

Accuracy

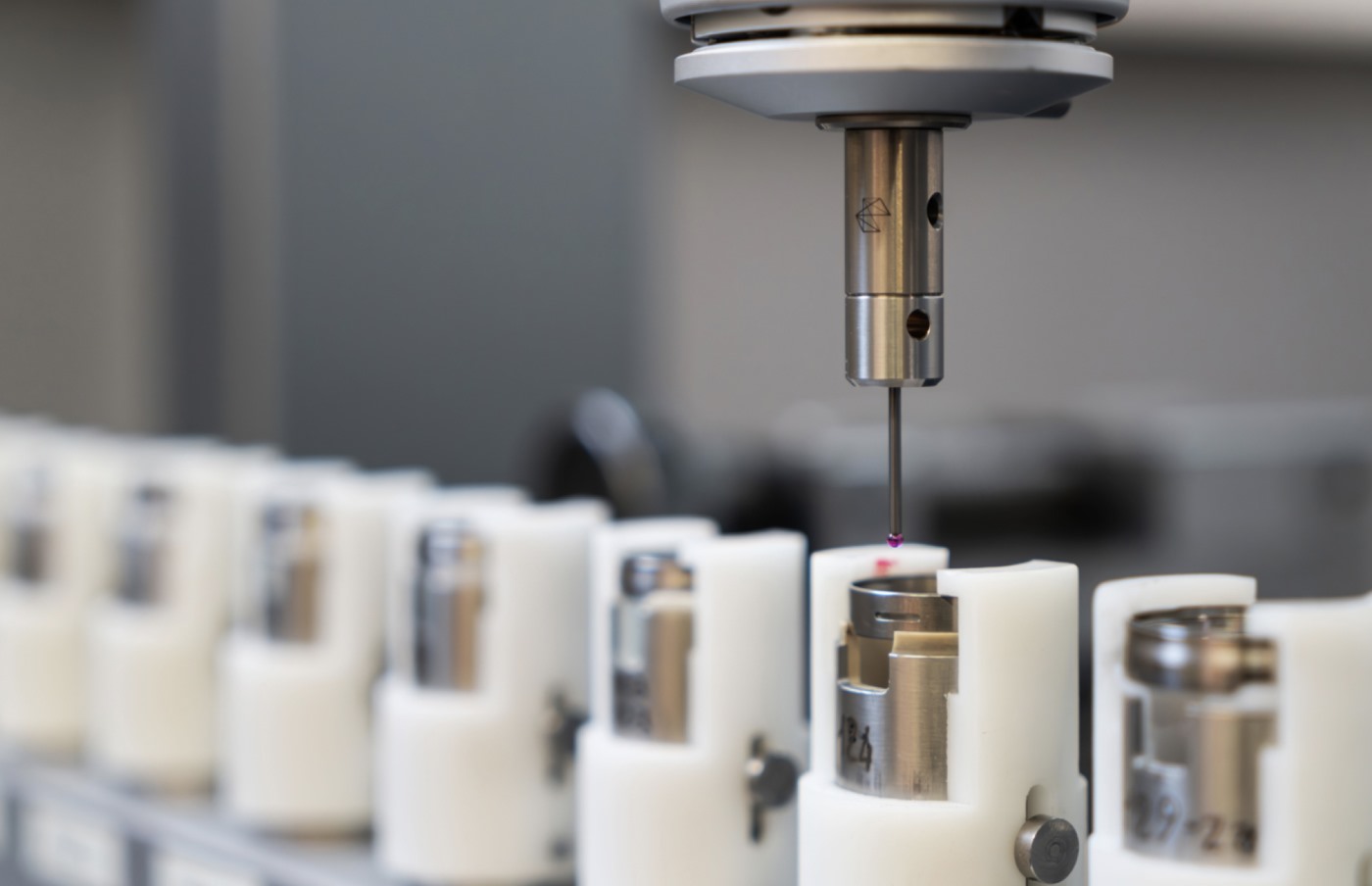

Gamba is continuously renewing its tool park to improve control of the tightest tolerances:

- Optical measuring machines

- Contact measuring machines

- Roundness and roughness gauges

Process control

To meet special requirements, Gamba provides 100% control with the support of digital instrumentation and automation systems, to monitor and certify process parameters.

Certified quality

The quality system has been certified since 1993 and updated to ISO 9001:2015 (Intertek No. 0614396-00).

Internal certification of instruments

Gamba has equipment with a precision of 0.1 microns for the certification of inspection instruments. Gamba ensures timeliness and precision.

+500

Hand tools

+1.000

Threaded gauges

+3.000

Pads, gauges and templates

Would you like more information?

Fill in the contact form or contact us directly at the following addresses: