Turning

A machine park for diameters from 2 mm up to 280 mm.

Turning with CNC machines is foreseen for parts of larger dimensions but above all for parts that represent greater challenges in terms of complexity, material hardness and precision.

Machining is completed on machining centres, with heat treatment and grinding.

34 CNC lathes:

- 14 bar lathes with bar capacity up to 65 mm

Marble - CMZ - 6 re-working lathes with automatic loading and max. 150 mm diameter

Doosan - CMZ - 6 lathes with manual loading for diameters up to 280 mm

Doosan - 3 hard turning and automatic loading lathes

Takamaz - 5 CNC sliding headstock lathes with bar capacity up to 20 mm

Citizen - Gildemeister - Sowin

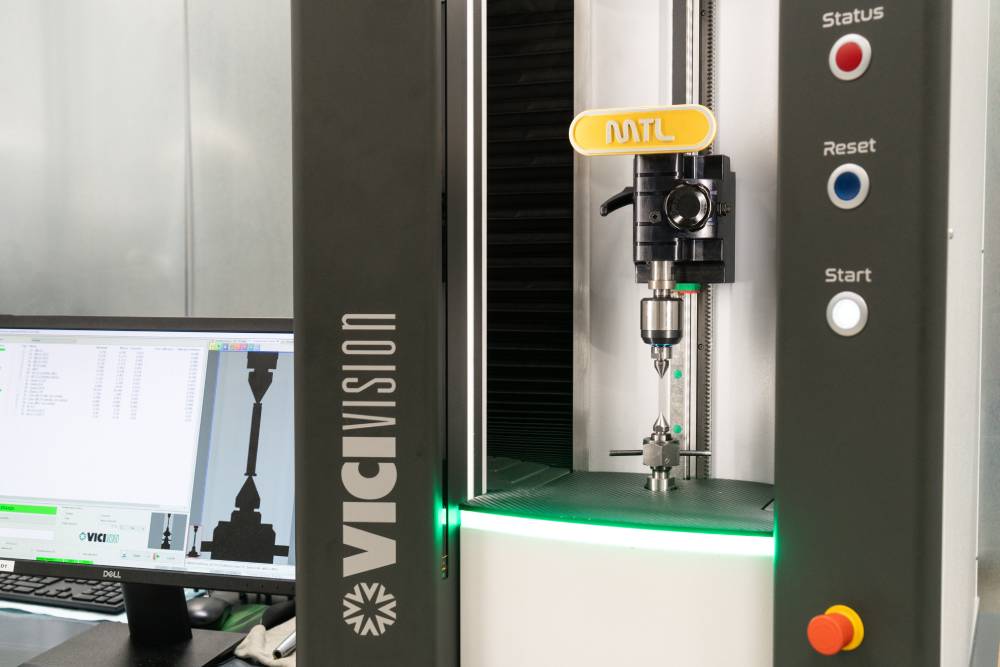

In-process control

Ensuring compliance with dimensions on complex machining operations, including with heat treatment, requires an organisation with adequate skills and equipment.

Other types of processing

We manage all stages of the production process internally to ensure quality control and adherence to schedules.

Would you like more information?

Fill in the contact form or contact us directly at the following addresses:

TEL

MAIL